Our Products

Why Choose Us?

Experienced Professionals

Our team of certified technicians and consultants bring years of expertise to every project, ensuring accuracy and reliability.

Reliable Support Services

With our repair, calibration, and training services, we help maintain your equipment’s peak performance.

Quality and Compliance Focus

Our commitment to quality, safety, and compliance is at the core of every service we provide.

Offering high quality construction solutions. Build Your Dream Now!

Ensuring Quality and Safety with Winstar NDT

Magnetic Particle Inspection (MPI) and Magnetic Crack Testing are essential non-destructive testing (NDT) methods used to detect surface and near-surface defects in ferromagnetic materials. Both techniques are widely utilized in industries such as aerospace, automotive, manufacturing, and construction, where the integrity of critical components is paramount. At Winstar NDT, we provide advanced MPI and Magnetic Crack Testing services in Chennai, ensuring high accuracy and reliable results for the safety and longevity of your assets. Magnetic Particle Inspection works by magnetizing a material, typically using a magnetic field. Once the material is magnetized, fine magnetic particles are applied to the surface. If there are any cracks or defects, they disrupt the magnetic field, causing the particles to accumulate at the defect site. This makes the crack or flaw visible under proper lighting conditions, enabling quick and efficient detection. Magnetic Crack Testing is essentially a subset of MPI, focused specifically on identifying cracks and discontinuities that could compromise material integrity. One of the primary advantages of MPI Testing is its ability to detect surface and near-surface flaws without causing any damage to the material being tested. This method is ideal for inspecting a variety of components such as welds, castings, forgings, and fabricated parts. Magnetic Crack Testing is particularly effective in detecting cracks in materials under stress or fatigue, making it a crucial service for ensuring the safety of structures and machinery used in high-risk applications. By identifying issues early, MPI helps prevent catastrophic failures and costly repairs. At Winstar NDT, we utilize the latest technology and expert technicians to perform MPI and Magnetic Crack Testing services. Our team is well-trained in the most effective inspection techniques and ensures that every test is carried out with precision. Whether you need to check small components or large structures, we offer flexible testing solutions tailored to your specific needs. We work across various industries to provide timely and reliable results that meet the highest quality and safety standards. Choosing Winstar NDT for your MPI and Magnetic Crack Testing needs means opting for quality, safety, and efficiency. Our commitment to delivering accurate, detailed results helps businesses avoid unexpected downtime and ensures compliance with industry regulations. We offer our services in Chennai and surrounding areas, making it easy for you to access professional, dependable testing that supports the ongoing performance and safety of your operations. Contact us today to schedule your MPI Testing and Magnetic Crack Testing services and experience the Winstar NDT difference.

Magnetic Particle Inspection (MPI) is a highly effective non-destructive testing (NDT) method used to detect surface and near-surface flaws in ferromagnetic materials. This method is essential in industries such as aerospace, automotive, manufacturing, and construction, where the safety and reliability of components are critical. MPI works by applying a magnetic field to the material and then using fine magnetic particles to reveal cracks, corrosion, or other imperfections that may compromise the material’s strength and durability. At Winstar NDT, we offer comprehensive MPI Inspection services in Chennai, ensuring that your components remain safe and operational. The MPI process begins by magnetizing the material to be tested, either through a direct or indirect method. Once magnetized, a fine powder or liquid containing magnetic particles is applied to the surface. If a defect is present, the magnetic field is disrupted, causing the particles to gather around the flaw. This accumulation of particles makes the defect visible to the inspector, who can then assess the severity and type of flaw. MPI Inspection is effective for detecting cracks, seams, laps, and other surface imperfections in materials like steel, castings, forgings, and welds. One of the key advantages of MPI Inspection is its ability to detect even the smallest surface flaws without damaging the material being tested. It is a rapid and cost-effective solution for inspecting parts that undergo stress or pressure during use, such as engine components, structural supports, and pipeline welds. MPI is particularly useful in detecting cracks that might not be visible to the naked eye, preventing potential failures that could lead to equipment breakdowns, accidents, or safety hazards. This method is commonly used in preventive maintenance, quality assurance, and regulatory compliance. At Winstar NDT, we are committed to providing the highest quality MPI Inspection services. Our team of trained professionals uses the latest technology and techniques to ensure accurate results. We offer flexible testing options, from small component inspections to large-scale structural testing. Whether you need MPI Inspection for a single part or for ongoing maintenance, we tailor our services to meet the specific requirements of your industry and project. Choosing Winstar NDT for your Magnetic Particle Inspection needs ensures reliable, thorough testing that helps maintain the integrity and safety of your assets. Our MPI Inspection services not only detect surface defects but also contribute to the overall performance and longevity of your equipment. We serve businesses across Chennai and surrounding areas, providing timely and efficient services that enhance your operational efficiency. Contact us today to learn more about our MPI Inspection services and how we can help ensure the safety and quality of your components.

Magnetic Particle Testing (MPT) is a widely used non-destructive testing (NDT) method that helps detect surface and near-surface defects in ferromagnetic materials. This method is especially effective in identifying cracks, seams, laps, and other imperfections that could compromise the structural integrity of components. At Winstar NDT, we offer expert Magnetic Particle Testing Services in Chennai, ensuring that your critical assets remain safe and reliable. Whether you're in the aerospace, automotive, or manufacturing industry, our MPT services are designed to detect flaws that might otherwise go unnoticed. Our Magnetic Particle Testing Services in Chennai are carried out using advanced equipment and techniques, ensuring the highest level of accuracy. The process involves magnetizing the material, after which fine magnetic particles are applied to the surface. If any surface or near-surface defects exist, the magnetic field will be disrupted, and the particles will accumulate around the flaw, making it visible to the inspector. This allows for quick detection of potential issues before they lead to failure, reducing downtime and maintenance costs. At Winstar NDT, we provide timely and reliable MPI testing services for a wide range of industries, ensuring the longevity and safety of your equipment. If you're looking for Magnetic Particle Testing Services near you, Winstar NDT is your local expert in Chennai and surrounding areas. Our highly skilled technicians provide professional MPI services to inspect and assess the condition of your components. We understand the importance of maintaining the safety and functionality of critical parts in high-risk industries. By choosing Winstar NDT, you gain access to reliable and efficient MPI services that meet the highest industry standards, ensuring the safety and operational readiness of your assets. At Winstar NDT, we take pride in offering top-quality Magnetic Particle Testing Services tailored to your needs. Our team is equipped with the latest technology and methodologies to ensure precise testing and accurate results. Whether you need testing for small components or large-scale industrial structures, we provide flexible solutions designed to meet your specific requirements. With our expertise, you can have peace of mind knowing that your equipment is thoroughly tested and safe for use. For comprehensive Magnetic Particle Testing Services in Chennai, trust Winstar NDT to deliver exceptional results every time. We provide cost-effective, non-destructive testing solutions that enhance safety and performance. Contact us today to schedule your MPI testing and learn more about how we can help ensure the quality and reliability of your materials and components. Our team is ready to assist with all your testing needs and provide the expertise you require.

Penetrant Testing (PT) is a widely used non-destructive testing method designed to detect surface-breaking defects such as cracks, porosity, and leaks in non-porous materials. This process involves applying a liquid penetrant to the surface of the material, allowing it to seep into any defects. After a cleaning and developing process, the penetrant trapped in the defects is made visible, revealing any issues. At Winstar NDT, we offer expert Penetrant Testing Services in Chennai, ensuring your components maintain the highest levels of safety and performance. Our Penetrant Testing Services in Chennai are carried out using the latest techniques and best practices to ensure accurate and reliable results. Whether you're inspecting critical parts like engine components, pressure vessels, or welds, our Penetrant Testing services will help identify any surface flaws that could compromise the structural integrity of your equipment. At Winstar NDT, we are committed to providing fast, efficient, and accurate PT testing that meets industry standards for quality assurance and safety. If you’re looking for Penetrant Testing Services near you, Winstar NDT is your local solution in Chennai and the surrounding areas. Our team of certified professionals is equipped to handle all your testing needs with precision and care. We are dedicated to providing high-quality services that ensure the safety and reliability of your materials, whether you're in the automotive, manufacturing, or aerospace industries. With our local presence, you can expect quick response times and personalized service. At Winstar NDT, we use only the most advanced methods and equipment to perform Penetrant Testing. Our skilled technicians ensure a thorough inspection, offering both visible and fluorescent penetrant options depending on the nature of the test. Whether you're testing small components or large structures, our team provides flexible and tailored solutions that meet your specific requirements. With a focus on safety, accuracy, and efficiency, we ensure that your materials are free from defects that could cause failures or downtime. For reliable Penetrant Testing Services in Chennai, look no further than Winstar NDT. We provide comprehensive non-destructive testing solutions that help ensure the quality, safety, and performance of your equipment. Contact us today to schedule your Penetrant Testing and discover how our expert team can assist with your testing needs. We are here to help you maintain high standards of safety and quality across all your operations.

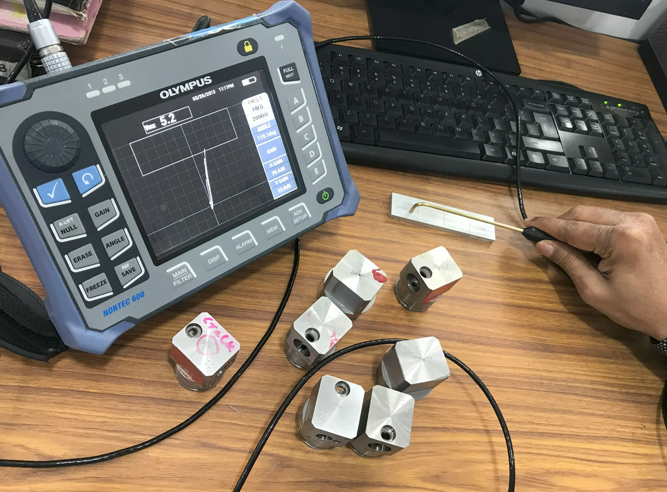

Ultrasonic Testing (UT) is a sophisticated non-destructive testing method used to detect internal defects, measure thickness, and assess the structural integrity of materials. By using high-frequency sound waves, UT can detect issues such as cracks, voids, and corrosion within a material without causing any damage. At Winstar NDT, we provide top-tier Ultrasonic Testing Services in Chennai to help ensure the safety and longevity of your components, from pipelines and welds to pressure vessels and more. Our Ultrasonic Testing Services in Chennai offer precise inspection for a wide range of materials, including metals, composites, and plastics. With the ability to penetrate deep into the material, ultrasonic waves can detect both surface and subsurface defects, making it an ideal solution for industries like aerospace, construction, and power generation. Winstar NDT’s expert team uses the latest equipment and techniques to ensure that your components are thoroughly inspected, providing peace of mind and safety for critical applications. If you’re looking for Ultrasonic Testing Services in Tamil Nadu, Winstar NDT is your trusted partner. We offer comprehensive UT testing services across the state, ensuring high-quality inspection for a wide array of industrial components. Our team is equipped with advanced ultrasonic testing tools that deliver reliable results for both small and large-scale applications. Whether you need to inspect pipelines, structural elements, or manufacturing components, Winstar NDT provides the expertise and technology to meet your specific needs. UT Testing in Chennai is critical for industries that rely on the structural integrity of their equipment. Winstar NDT provides fast and efficient ultrasonic testing to help detect internal defects that could compromise safety or performance. By using advanced ultrasonic probes and techniques, our team delivers accurate results that meet industry standards. With a focus on minimizing downtime, our UT testing services allow you to identify potential issues early, reducing the need for costly repairs and preventing catastrophic failures. For those searching for UT Testing Near Me, Winstar NDT is conveniently located in Chennai and offers on-site ultrasonic testing services. Our team is ready to assist with all your testing requirements, providing reliable and accurate assessments at your location. Whether you need routine inspections or specialized testing for unique materials, Winstar NDT ensures that you receive professional and timely services tailored to your needs. If you’re looking for professional Ultrasonic Testing Services in Chennai or Tamil Nadu, Winstar NDT offers reliable, non-destructive testing solutions that guarantee the safety and quality of your materials. Contact us today to schedule your UT testing and learn more about how we can help maintain the integrity of your critical components. With our expertise and cutting-edge technology, we provide comprehensive solutions for all your testing needs.

Radiography Testing (RT) is a powerful non-destructive testing (NDT) method that uses X-rays or gamma rays to examine the internal structure of materials and components. By revealing hidden defects such as cracks, voids, or corrosion, RT testing plays a critical role in maintaining the safety and reliability of assets. At Winstar NDT, we offer high-quality Radiography Testing Services in Chennai, providing precise, clear imaging that ensures the integrity of your materials and components without causing any damage. Our Radiography Testing Services in Chennai are conducted using state-of-the-art equipment and techniques to provide highly detailed imaging of internal defects. Whether it's for weld inspections, casting evaluations, or structural integrity assessments, our RT services help identify potential issues before they lead to equipment failure or safety hazards. Winstar NDT ensures that your parts and structures are thoroughly inspected, providing the critical insights necessary for preventative maintenance and quality assurance. For those seeking Radiography Testing Services in Tamil Nadu , Winstar NDT offers reliable and accurate testing solutions across the region. Our certified technicians utilize advanced radiographic equipment to perform comprehensive tests on various materials, including metals, plastics, and composites. Whether you’re involved in construction, manufacturing, or aerospace, our RT services provide vital information to help maintain the safety and reliability of your components, preventing costly repairs and downtime. RT Testing in Chennai provides an efficient and effective method for detecting internal flaws that are not visible on the surface. By using X-rays or gamma rays, RT testing allows us to examine the integrity of materials and components from the inside out, offering precise imaging of any internal defects. Whether it’s for routine maintenance or regulatory compliance, Winstar NDT provides detailed, accurate RT testing to help you make informed decisions regarding the condition of your equipment. Looking for RT Testing Near Me? Winstar NDT is your trusted partner for Radiography Testing in Chennai and surrounding areas. We provide convenient on-site RT testing services that ensure your materials and components meet industry standards for quality and safety. With our expertise and advanced radiographic technology, we deliver precise results in a timely manner, helping businesses minimize risks and ensure compliance. For reliable and professional Radiography Testing Services in Chennai and Tamil Nadu, Winstar NDT offers expert solutions to detect internal defects and assess the structural integrity of your components. Contact us today to schedule your RT testing and learn more about how our team can assist you in maintaining the safety, quality, and performance of your assets.

Visual Testing (VT) is one of the most straightforward yet essential non-destructive testing (NDT) methods, used to detect surface defects, corrosion, cracks, and other visible issues in materials and components. This method relies on direct visual inspection, often aided by tools such as magnifying glasses, mirrors, and cameras, to ensure that materials meet quality and safety standards. At Winstar NDT, we provide comprehensive Visual Testing Services in Chennai, offering reliable and detailed inspections that help maintain the integrity and longevity of your critical components. Our Visual Testing Services in Chennai are performed by highly skilled technicians who are trained to identify even the smallest surface imperfections. Whether it’s inspecting welds, castings, or structural components, our team ensures that your materials are free from defects that could compromise their performance. Visual Testing is particularly effective for initial inspections and for monitoring the condition of materials in high-risk environments. With Winstar NDT’s services, you can ensure the highest quality and safety of your assets through routine and detailed inspections. Winstar NDT offers Visual Testing Services in Tamil Nadu , providing professional and reliable inspections throughout the region. Whether you're in manufacturing, construction, or any other industry that requires high-quality materials, our VT services ensure that your components are defect-free and meet safety standards. Our expert team uses the latest tools and techniques to perform efficient inspections, providing clear and accurate results that support your maintenance and quality control processes. We are dedicated to helping businesses in Tamil Nadu maintain the safety and functionality of their equipment. Visual Testing is often the first line of defense in identifying surface defects, and Winstar NDT offers the expertise and technology needed for thorough inspections. We are committed to providing cost-effective, high-quality services that help prevent defects from causing potential failures or safety hazards. Our experienced team works with a range of industries to deliver detailed and reliable inspection results that can be used for corrective actions, maintenance planning, and regulatory compliance. By choosing Winstar NDT, you ensure the ongoing safety, quality, and performance of your components. For expert Visual Testing Services in Chennai and Tamil Nadu, Winstar NDT provides comprehensive non-destructive testing solutions designed to meet your specific needs. Contact us today to schedule your visual inspection and learn more about how our services can help you ensure the integrity and safety of your materials. With our dedicated team and advanced technology, we ensure that your components are thoroughly inspected and meet the highest standards of quality and safety.

Eddy Metal Sorting is a specialized technique used to separate and sort metallic materials based on their conductivity and magnetic properties. This method utilizes the principles of eddy current testing, which induces a magnetic field to identify different types of metals, allowing for efficient sorting. At Winstar NDT, we offer expert Eddy Metal Sorting services in Chennai, providing businesses with precise and reliable sorting solutions to optimize material processing and enhance operational efficiency. Our Eddy Metal Sorting in Chennai service provides businesses with a fast and accurate way to identify different metals in bulk materials. This process is especially beneficial in industries such as recycling, manufacturing, and material handling, where sorting metals efficiently can significantly reduce costs and improve productivity. By using advanced eddy current technology, Winstar NDT helps you ensure that materials are correctly identified and separated, preventing contamination and enhancing material quality. If you're searching for Eddy Metal Sorting Near Me, Winstar NDT offers local services in Chennai and the surrounding areas. Our experienced technicians use state-of-the-art equipment to provide efficient and reliable sorting solutions. Whether you need to sort scrap metal, identify different alloys, or separate metals in your manufacturing process, our team is here to offer the precise solutions you need. With our focus on accuracy and efficiency, you can trust Winstar NDT for all your eddy metal sorting requirements. At Winstar NDT, we specialize in providing high-quality Eddy Metal Sorting services that help improve the efficiency and quality of your operations. Our team is equipped with the latest technology, ensuring that the sorting process is done quickly, accurately, and with minimal waste. We offer tailored solutions based on your specific material sorting needs, whether for small-scale operations or large industrial applications. By choosing Winstar NDT, you benefit from expert services that streamline your processes and enhance the overall quality of your materials. For efficient Eddy Metal Sorting in Chennai, trust Winstar NDT to provide the expert solutions you need. Contact us today to learn more about our sorting services and how we can help optimize your material handling process. With our skilled team and advanced technology, we ensure that your metals are accurately sorted and ready for use in your operations.

Eddy Current Testing (ECT) is a widely used non-destructive testing (NDT) method that utilizes electromagnetic induction to detect surface and near-surface defects in conductive materials. By generating eddy currents in the material and measuring their response, ECT can identify cracks, corrosion, and other flaws that could compromise the integrity of the material. At Winstar NDT, we provide expert Eddy Current Testing Services to ensure the safety and reliability of your critical components, whether you’re in aerospace, automotive, or industrial manufacturing. Our Eddy Current Testing Services in Chennai are designed to provide precise and reliable results for a wide range of materials, including metals, alloys, and other conductive materials. This testing method is highly effective in detecting surface-breaking cracks, material degradation, and other anomalies without damaging the component. With Winstar NDT's expert team and advanced technology, you can rest assured that your components are thoroughly inspected, ensuring the safety and longevity of your assets. If you're looking for Eddy Current Testing Services Near Me, Winstar NDT is your trusted local provider in Chennai and the surrounding areas. We offer on-site and off-site testing services that are fast, efficient, and precise. Our experienced technicians use state-of-the-art equipment to perform detailed inspections, allowing us to identify flaws that are not visible to the naked eye. Whether you need routine inspections or specialized testing, our team is dedicated to providing the best possible service, tailored to your specific needs. At Winstar NDT, we specialize in delivering high-quality Eddy Current Testing Services that help you maintain the safety, reliability, and performance of your components. Our team uses advanced eddy current testing equipment, ensuring quick and accurate detection of defects. Whether you are testing for corrosion, cracks, or other surface issues, we offer solutions that meet industry standards for quality and compliance. By choosing Winstar NDT, you benefit from professional testing services that help reduce downtime and prevent costly failures. For reliable Eddy Current Testing Services in Chennai, trust Winstar NDT to deliver comprehensive, non-destructive testing solutions for all your material inspection needs. Contact us today to schedule your Eddy Current Testing and learn how we can assist in ensuring the quality and safety of your components. Our expert team is ready to provide efficient, accurate testing tailored to your specific requirements.

Eddy Current Testing (ECT) is a highly effective non-destructive testing method used to detect surface and near-surface flaws in conductive materials. By generating eddy currents through electromagnetic induction, this technique allows for the precise detection of cracks, corrosion, and other defects that may compromise material integrity. Winstar NDT offers expert ECT Testing services, ensuring the safety and reliability of your components, especially in critical industries such as aerospace, automotive, and manufacturing. Our ECT Testing in Chennai provides detailed and accurate inspections for a variety of materials, including metals, alloys, and composites. The ability of ECT to detect even the smallest defects in conductive materials makes it an ideal choice for industries requiring high-quality and reliable components. Winstar NDT’s team of trained professionals uses state-of-the-art equipment to perform thorough and efficient tests, ensuring your components meet the highest standards of safety and performance. For those looking for ECT Testing Near Me, Winstar NDT offers convenient, local services throughout Chennai and surrounding areas. We specialize in providing on-site and off-site testing services tailored to your needs, offering quick, reliable results. Our technicians are equipped with the latest eddy current testing tools to perform accurate inspections, detecting even the most hidden flaws in your components. Whether for routine maintenance or specialized inspections, Winstar NDT ensures that your assets are inspected with precision and care. Winstar NDT’s ECT Testing services offer a fast, non-invasive way to ensure the structural integrity of your components. Our technicians are highly skilled and experienced, ensuring that each test is conducted with the utmost accuracy. We use the latest technology to perform detailed inspections, helping you identify flaws before they lead to failures or safety risks. By choosing Winstar NDT, you benefit from reliable testing services that improve the quality and reliability of your materials and products. For accurate and professional ECT Testing in Chennai, look no further than Winstar NDT. Contact us today to schedule your testing and learn more about how our team can assist with your material inspection needs. We are dedicated to providing high-quality, non-destructive testing solutions to ensure the safety and performance of your critical components.

Eddy Crack Testing is a specialized application of eddy current testing (ECT) that focuses on detecting cracks and other surface-breaking defects in

conductive materials. By inducing eddy currents into the material and measuring the response, this method can identify even the smallest cracks that

may not be visible to the naked eye. At Winstar NDT, we provide expert Eddy Crack Testing services to ensure the integrity and safety of your components,

helping to prevent costly failures in critical applications such as aerospace, automotive, and industrial manufacturing.

Our Eddy Crack Testing in Chennai is designed to deliver fast, reliable, and accurate results for detecting cracks in metals and alloys. This method is especially

effective for inspecting welds, turbine blades, pipes, and other components that are subject to high stresses and wear. Winstar NDT uses advanced eddy current

equipment and techniques to precisely locate cracks and ensure that your materials and components meet the highest standards of safety and performance. Trust our

skilled technicians to provide thorough inspections with minimal disruption to your operations.

If you're looking for Eddy Crack Testing Near Me, Winstar NDT offers convenient on-site testing services in Chennai and nearby regions. Our team of experts will

come to your location and perform the necessary tests to detect cracks and other defects in your components. Whether you need routine inspections or have specific

concerns about material integrity, our Eddy Crack Testing services are designed to provide fast, efficient, and accurate results without compromising the quality of

your equipment.

Winstar NDT provides Eddy Crack Testing services that help you identify critical flaws in your materials before they lead to failures. Our team uses state-of-the-art

eddy current equipment that allows for the rapid and non-destructive inspection of your components. Whether you are dealing with complex machinery, aerospace parts,

or industrial components, our Eddy Crack Testing services will give you the confidence to know that your equipment is free from dangerous cracks and defects.

For reliable Eddy Crack Testing in Chennai and nearby areas, Winstar NDT is your trusted partner. Contact us today to schedule your Eddy Crack Testing and ensure the

continued safety and performance of your critical components. Our team is ready to provide high-quality, non-destructive testing solutions tailored to your needs,

helping you maintain the integrity and reliability of your materials.

Ultrasonic Pulse Velocity (UPV) Testing is a non-destructive testing (NDT) method used to assess the quality and strength of materials like concrete,

metals, and composite materials. By measuring the velocity of an ultrasonic pulse traveling through the material, this technique provides insights into the

material’s internal structure, identifying any flaws, cracks, or voids that may compromise its integrity. At Winstar NDT, we offer professional

Ultrasonic Pulse Velocity Testing Services in Chennai to ensure your materials meet the highest

standards of safety and quality.

At Winstar NDT, we offer a wide range of NDT Equipment Repair Services in Chennai designed to restore the full functionality of your tools. Whether you use ultrasonic

testing (UT) devices, magnetic particle inspection (MPI) equipment, radiographic testing (RT) machines, eddy current testing (ECT) tools, or visual testing

(VT) instruments, we provide comprehensive repair solutions. Our skilled technicians are equipped to handle calibration, part replacements, and troubleshooting

to fix issues and ensure your equipment meets the required industry standards. By addressing the root causes of malfunction, we help you reduce downtime and

maintain the reliability of your NDT processes.

Ensure the accuracy and reliability of your NDT instruments with NDT Equipment Calibration Testing Services in Chennai by Winstar NDT. Whether you require

periodic calibration or urgent adjustments, our team is ready to assist. Contact us today to schedule your calibration service and maintain the highest standards

of safety and precision in your operations.

If you’re looking for professional Infrared Thermography Testing Services in Chennai , trust Winstar NDT for accurate, reliable, and cost-effective solutions.

Contact us today to learn more about our services or to schedule an inspection. Let us help you ensure the safety and performance of your assets with advanced

infrared thermography technology.

If you’re looking for accurate and reliable Hardness Testing Services in Chennai , Winstar NDT is here to help. Our skilled team and advanced testing solutions

ensure the highest levels of quality and precision. Contact us today to learn more about our services or to schedule a consultation. Let us help you achieve your

quality assurance goals with confidence.

Ensure the quality and compliance of your materials with Positive Material Identification Services in Chennai by Winstar NDT. Our expertise, advanced equipment,

and commitment to excellence make us the preferred choice for PMI testing. Contact us today to learn more about our services or to schedule an inspection. Let us

help you achieve your quality assurance goals with confidence.

Ensure the reliability and efficiency of your machinery with Vibration Analysis Services in Chennai by Winstar NDT. Our expert team and advanced diagnostic

tools deliver precise results, helping you avoid unexpected failures and maintain a smooth operation. Contact us today to schedule an analysis or learn more

about our comprehensive range of services. Let us help you achieve operational excellence through proactive maintenance.

Discover the benefits of cutting-edge Advanced NDT Testing Services in Chennai with Winstar NDT. Our expertise, advanced tools, and commitment to excellence

ensure your operations remain safe and efficient. Contact us today to learn more about our services or to schedule a consultation. Let us partner with you to

achieve unparalleled quality and reliability.

Our Recent Works

What Our Clients Say!